The Metals And Welding Specialities ECOCR-B electrodes are manufactured using premium cobalt-chromium alloys that maintain hardness and integrity even at elevated temperatures. They exhibit exceptional resistance to galling, oxidation, and impact, making them suitable for both static and dynamic wear environments. The deposit produced by these electrodes provides a tough and durable surface with a typical hardness range of 40–45 HRC, which remains stable during thermal cycling or under continuous exposure to heat.

These Cobalt Base ECOCR-B electrodes are particularly effective for rebuilding and overlaying components exposed to hot metal wear or corrosion. Common applications include turbine blades, valve seats, forging dies, pump sleeves, and hot shear blades, where the combination of wear and corrosion resistance is critical. The electrodes offer a smooth and stable arc, easy slag removal, and minimal spatter, allowing welders to achieve clean and precise weld deposits with excellent bead appearance.

Metals And Welding Specialities ensures that each batch of ECOCR-B welding electrodes meets stringent international standards for chemical composition and performance. The cobalt, chromium, and tungsten balance in this alloy provides superior metallurgical bonding and ensures the weld metal retains its properties even under severe mechanical stress. The weld deposit is nonmagnetic and maintains strength and toughness up to 600°C, making it a preferred choice for industries such as power generation, petrochemical processing, and aerospace maintenance.

Our Cobalt Base Alloys ECOCR-B electrodes also demonstrate remarkable resistance to corrosion from acids, oxidizing environments, and molten metals. The uniform metallurgical structure reduces cracking tendencies and enhances machinability after welding. These features make ECOCR-B a dependable solution for applications requiring long service life and reduced downtime due to part replacement or maintenance.

Metals And Welding Specialities continues to lead in providing high-performance welding consumables that align with the most demanding industrial requirements. With consistent quality, precise chemical balance, and proven durability, the ECOCR-B Welding Electrodes are an ideal choice for achieving long-lasting, wear-resistant surfaces in harsh operating environments.

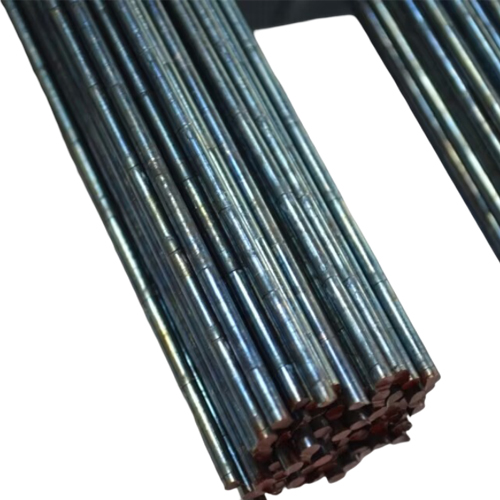

Specification Cobalt Base Alloys ECOCR-B Welding Electrodes

Classification

AWS A5.13, ECOCR-B

Form

Welding Electrode, Welding Rods

Type Of Current

Direct Current Electrode Positive (DCEP)

Size

2.6 mm (3/32")

3.2 mm (1/8")

4.0 mm (5/32")

5.0 mm (3/16")

6.4 mm (1/4")

Welding Positions

All positions (F, V, OH, H)

AWS ECOCR-B Welding Electrodes Application & uses

- Petroleum

- Chemical plant

- Power sector

- Gas Industry

- Hardware tools

- Metallurgy

- Machinery

- Construction

- Shipbuilding

Equivalent Grade Of AWS ENiCrMo-4 Coated Electrodes

Class

UNS

Stellite

ECOCR-B

W73042

Stellite 12

Cobalt Base Alloys ECOCR-B Welding Electrodes Chemical Composition

Grade

C

Si

Mn

Cr

W

Co

ECoCr-B

1.43

0.56

0.98

31.62

8.67

Balance